Food Services

The effective alternative to ion exchange water softening

People in the food services sector appreciate the problems associated with hard water limescale. Until recently, the options were to use ion exchange softening – perhaps polyphosphate, with all the secondary problems and issues of both, or use one of the inefficient electronic or magnetic systems that simply don’t work very well, and in independently conducted evaluations rarely achieve even 50% efficiency.

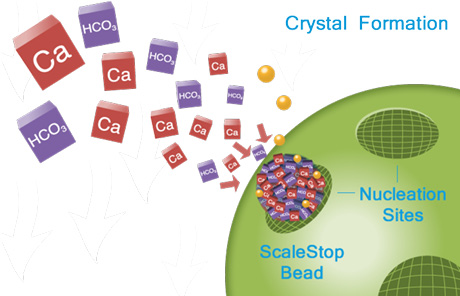

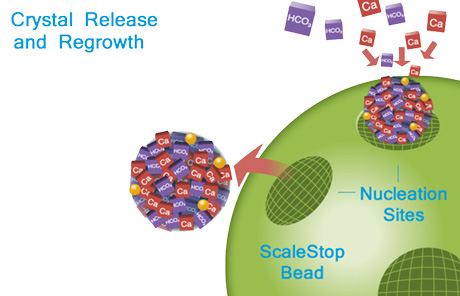

Scale Stop is an innovation using a proven process known as Template Assisted Crystallisation (TAC) In simple terms this causes the scale forming crystals to stick to each other at a microscopic leveland not to metal surfaces. This process adds nothing to the water and takes nothing away. The calcium and magnesium removed by ion exchange softening are desirable minerals for quality water.

Practical and operational advantages

With ion exchange softening and polyphosphate cartridge treatment you have to regularly replace or top up the system which costs money for service calls or takes up valuable staff time. The life in service of both is quite limited, particularly with hardness levels above 180ppm. The most common situation is that the replacement or top up is not carried out as often as it should be – and sometimes not done at all. It’s one of those jobs that most people don’t want to do and put off until tomorrow! Traditional POU (Point of Use) equipment protection such as phosphate and cation resin cartridges have relatively low flow rates and short effective life with typical change out at 6 months or less….especially in hard water areas above 180ppm.

Using ScaleStop POU cartridges, replacement is after a minimum of 1 year – no matter what the level of water hardness is.

Scale Stop uses both cartridge and pressure vessel systems. For cartridge systems with flow rates of up to 16 litres a minute continuous flow (that’s 24/7/365) the recommendation is to change the cartridge annually. A Scale Stop replacement cartridge or media change in a pressure vessel cost is significantly less than the annual bills for multiple cartridge or media changes in system of similar size, and change out periods can be extended if you have lower flow rates. With only one service call a year, costs can be significantly reduced.

A full range of systems from 1 litre a minute flow rate are available. Systems above 32 litres a minute flow rate, which are ideal for whole store Point Of Entry (POE) protection operate for 3 years between media changes.

POE systems such as the TurboTAC or TTAC Compact combine a carbon pre filter which removes sediment and chemicals – especially chlorine, for better tasing and crystal clear water as well as scale protection for every machine and appliance on site. This means no changing of cartridges in customer facing areas and many fewer service calls.

Maintaining the system

Global Approval

Scale Stop has Global approval with Marriott Hotels and McDonald’s Restaurants and provides protection on Concordia Coffee machines, Groen steam & combi ovens and Manitowoc ice machines. Also Noritz boilers (branded Baxi and Andrews water heaters in the UK) and with other hotels, restaurants, coffee chains, food services equipment and water heating manufacturers. All the commercial testing and approval is reinforced by independent third party verifications using the Internationally recognised German DVGW-W512 testing protocol for hard scale prevention. Under this test protocol, Scale Stop achieved a repeatable 99.6% efficiency rating.

Who's using ScaleStop...